Mere Christianity Study Guide: An In-Depth Plan

This comprehensive study guide delves into C.S. Lewis’s pivotal work, offering insightful questions for reflection and deeper understanding of Christian apologetics.

Adapted from wartime BBC broadcasts, Mere Christianity presents a compelling case for faith, accessible to all seeking truth and spiritual guidance.

Explore the core tenets of Christianity, fostering discussion and personal meditation through this meticulously crafted companion to Lewis’s enduring classic.

Welcome to this in-depth exploration of C.S; Lewis’s Mere Christianity, a cornerstone of 20th-century Christian thought. This study guide is designed to enhance your understanding and engagement with Lewis’s masterful articulation of the Christian faith, originally delivered as a series of radio broadcasts during World War II (1941-1944).

This resource provides a framework for individual study or group discussion, offering thought-provoking questions and prompts for meditation. It aims to unpack the core arguments presented by Lewis, encouraging critical thinking and personal reflection on the fundamental beliefs of Christianity.

The guide isn’t intended to replace the book itself, but rather to serve as a companion, illuminating its nuances and facilitating a deeper appreciation for Lewis’s apologetic approach. We will explore how Lewis defends the Christian faith to the layperson, making complex theological concepts accessible and relatable. Prepare to embark on a journey of intellectual and spiritual discovery, as we delve into the ‘mere’ essentials of Christianity.

This guide will help you apply these timeless principles to modern life, fostering a more informed and vibrant faith.

The Historical Context of Mere Christianity

Mere Christianity emerged from a specific historical moment: the tumultuous years of World War II (1941-1944). C.S. Lewis delivered the initial talks as a series of radio broadcasts on the BBC, reaching a British public grappling with immense uncertainty, loss, and a search for meaning amidst widespread conflict.

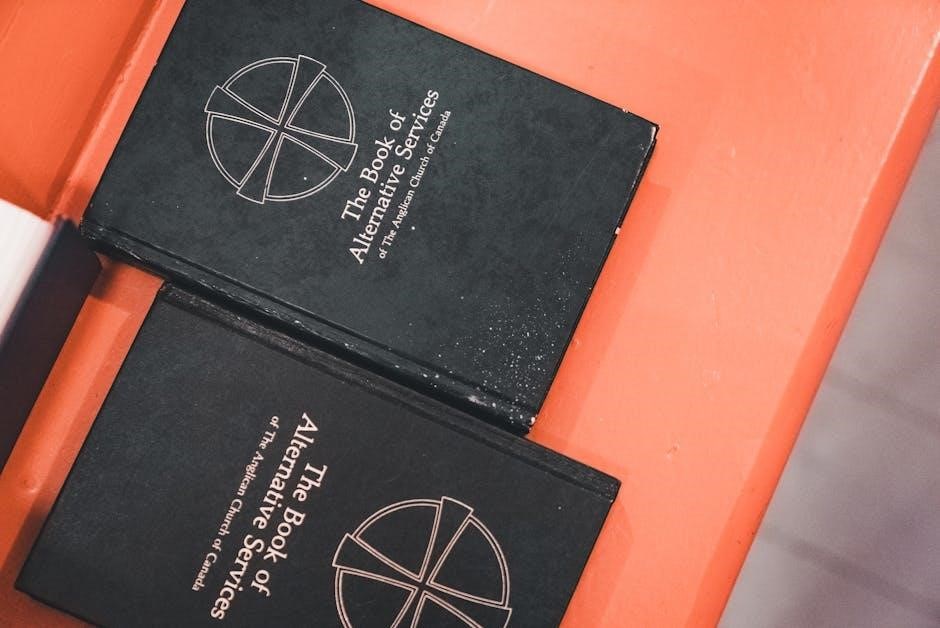

The broadcasts weren’t intended as a systematic theological treatise, but rather as a reasoned defense of basic Christian beliefs, presented in a way that resonated with a broad audience. Lewis sought to identify the common ground – the ‘mere’ Christianity – shared by most Christian denominations, stripping away sectarian differences.

This context profoundly shaped the book’s tone and content. Lewis addressed a society questioning traditional values and seeking moral anchors. He aimed to demonstrate the rationality and relevance of Christianity, offering a hopeful message during a dark period. Understanding this wartime backdrop is crucial for appreciating the book’s enduring appeal and its continued relevance in a world still facing complex challenges.

The need for shared values and a moral compass was paramount during this era, influencing Lewis’s focus on fundamental principles.

C.S; Lewis: Life and Influences

Clive Staples Lewis (1898-1963) was a British author, scholar, and Christian apologist whose profound impact extends far beyond Mere Christianity. His early life was marked by a rigorous education, initially under private tutors, and later at Oxford University and University College.

Lewis’s intellectual journey was complex. He initially rejected Christianity, embracing atheism during his youth. However, through conversations with friends, including J.R.R. Tolkien, and a growing sense of spiritual longing, he experienced a conversion to Christianity in 1931.

This conversion deeply influenced his writing. He became a prominent voice for Christian apologetics, skillfully blending reason, imagination, and literary artistry. His influences included classical literature, mythology, and philosophy. Mere Christianity reflects his ability to articulate Christian beliefs in a clear, accessible, and intellectually stimulating manner, drawing upon a lifetime of learning and personal experience.

Lewis’s background in literature allowed him to connect with readers on an emotional and intellectual level.

Book I: The Case for Christianity

Lewis presents compelling arguments for the existence of God, exploring reason, moral law, and innate human desires as evidence supporting Christian belief and truth.

Chapter 1: The Argument from Reason

C.S. Lewis initiates his case for Christianity by examining the very faculty we use to question its truth: reason itself. He posits that if our minds are simply products of a mindless universe, then our thoughts hold no inherent truth value.

If natural selection solely shaped our intellects for survival, why should we trust them to grasp objective reality? Lewis argues that a universe governed by chance would not reliably equip us with the ability to discern truth from falsehood.

He illustrates this with a compelling analogy: if a detective is relying on clues within a case, the clues themselves must be trustworthy. Similarly, if we are to trust our reasoning, there must be a rational source – a divine Mind – behind the universe.

This chapter challenges readers to consider the preconditions necessary for rational thought and to explore the implications of a universe without a rational foundation. Lewis’s argument isn’t a proof, but a powerful invitation to consider the source of our cognitive abilities.

Chapter 2: The Argument from Desire

Lewis transitions from reason to the deeply human experience of longing – the innate desire for something beyond the material world. He argues that this universal human yearning isn’t simply a product of evolution or conditioning, but a signal pointing towards a transcendent reality.

He uses the analogy of hunger; hunger doesn’t simply feel like something exists to satisfy it, it implies the existence of food. Similarly, our deepest desires – for joy, beauty, and fulfillment – suggest the existence of an object capable of satisfying them.

Lewis contends that these desires are not illusions, but genuine responses to a real, though currently unseen, object of our longing. He proposes that this object is God, the source of all joy and the ultimate fulfillment of our deepest needs.

This chapter encourages introspection, prompting readers to examine their own longings and consider whether they might be pointing towards a divine source. It’s a deeply personal argument, rooted in the universal human experience of dissatisfaction and the search for meaning.

Chapter 3: The Third Argument – The Moral Law

Lewis introduces his most famous argument: the existence of a universal moral law. He observes that humans consistently judge actions as right or wrong, not merely based on personal preference, but according to an objective standard. This isn’t simply about societal norms, but a deeper sense of obligation.

He illustrates this with examples of blame and praise; we don’t just say someone dislikes an action, we say it’s wrong. This implies a standard against which actions are measured, a standard that exists independently of human opinion.

Lewis argues that this moral law cannot originate from within us, as our desires are often self-serving. Nor can it originate from society, as societal norms are constantly changing and often morally questionable.

Therefore, he concludes, the moral law must come from a source outside of ourselves – a divine lawgiver. This lawgiver is God, who has imprinted a sense of right and wrong onto the human conscience, providing a foundation for morality and justice.

The Nature of the Moral Law

Lewis clarifies that the Moral Law isn’t a set of instructions, like rules in a game, but rather a fundamental principle governing behavior. It’s not about achieving a specific outcome, but about the way we act, the intention behind our choices.

He emphasizes that the Law is unwritten and universal, recognized across cultures and throughout history. While specific applications may vary, the core principles – such as honesty, fairness, and compassion – remain consistent.

The Moral Law isn’t about maximizing pleasure or minimizing pain, as these are subjective experiences. It’s about doing what is right, regardless of personal consequences. Sometimes, following the Moral Law requires sacrifice and discomfort.

Lewis stresses that we don’t discover the Moral Law by observing the world, but by reflecting on our own inner sense of obligation. It’s a law “within” us, a voice that tells us what we ought to do, even when we don’t want to.

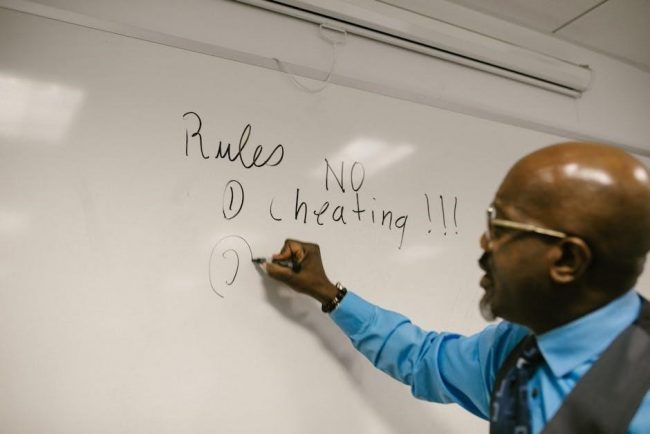

Distinguishing Moral Law from Social Conventions

Lewis meticulously differentiates between the timeless Moral Law and transient social conventions, highlighting that customs vary drastically across cultures and eras. What is considered polite or acceptable in one society may be offensive in another, demonstrating their relative nature.

He argues that true morality transcends cultural norms; it’s not simply what society dictates, but a deeper, inherent sense of right and wrong. Social conventions aim for convenience and order, while the Moral Law appeals to our conscience.

A key distinction lies in the feeling of disapproval. Breaking a social convention might elicit mild criticism, but violating the Moral Law evokes a sense of profound guilt and shame.

Lewis points out that social conventions are often arbitrary, lacking a rational basis beyond tradition. The Moral Law, however, feels grounded in objective truth, a universal standard against which we measure our actions. Recognizing this difference is crucial for discerning genuine morality.

Book II: Christian Beliefs

This section explores foundational Christian doctrines, including the Trinity and Incarnation, offering a rational examination of core beliefs and their profound significance.

Chapter 1: The Separation of the Powers

Lewis initiates a crucial discussion concerning the divine power and its distinct separation from created powers. He posits that God, as the uncreated power, operates fundamentally differently from any power found within the universe.

He clarifies that created powers – those exhibited by beings or forces within creation – are always derived and limited. They are not self-sufficient and depend entirely on God for their existence and operation. This distinction is vital for understanding the nature of miracles and divine intervention.

The chapter emphasizes that God’s power isn’t simply a greater quantity of the same kind of power seen in creation, but a qualitatively different power altogether. This difference allows for genuine novelty and transcends the limitations of natural law.

Lewis uses analogies to illustrate this point, highlighting how a being outside of space and time could interact with the universe without being bound by its constraints. This foundational concept sets the stage for exploring more complex doctrines like the Incarnation and the Atonement, demonstrating God’s unique ability to act within and beyond creation.

Chapter 2: The Trinity

Lewis tackles the challenging doctrine of the Trinity, acknowledging its inherent difficulty for human comprehension. He emphasizes that the Trinity isn’t a mathematical problem to be solved, but a reality to be approached with humility and openness.

He explains that the Christian belief in God as Father, Son, and Holy Spirit isn’t a belief in three separate gods, but in one God existing eternally in three distinct persons. This isn’t a contradiction, but a revelation about the very nature of divine life.

Lewis utilizes the analogy of a human being – body, mind, and spirit – to illustrate how three distinct aspects can constitute a single, unified entity. While imperfect, this analogy helps grasp the concept of three-in-one.

The chapter stresses that the Trinity isn’t merely an abstract theological concept, but a fundamental truth about God’s relational nature. God is love, and love requires a lover, a beloved, and a bond of love – mirroring the relationships within the Trinity. Understanding this is crucial for comprehending God’s character and his interaction with humanity.

Chapter 3: The Incarnation

Lewis confronts the astonishing claim that God became man in the person of Jesus Christ – the Incarnation. He acknowledges the sheer audacity of this idea, yet argues it’s the most satisfying explanation for humanity’s deepest longings and the universe’s inherent meaning.

He explores why God would choose to enter into human history, suffering and ultimately dying on the cross. Lewis posits that God isn’t merely a powerful being who demands obedience, but a loving Father who desires reconciliation with his rebellious children.

The Incarnation demonstrates God’s solidarity with humanity, experiencing our joys and sorrows, our triumphs and failures. It’s not simply a rescue mission from the world, but a redemption of the world, restoring creation to its intended glory.

Lewis emphasizes that Jesus isn’t merely a “good man” or a moral teacher, but the God-man, possessing both fully divine and fully human natures. This unique identity is essential for understanding his role as mediator between God and humanity, and the significance of his sacrifice.

Understanding the Significance of the Incarnation

Lewis meticulously unpacks the profound implications of God becoming human. The Incarnation isn’t a detached theological concept, but a pivotal event reshaping our understanding of God, humanity, and the universe itself.

He argues that through the Incarnation, God reveals his character in a uniquely accessible way. We can now know God not just through abstract reasoning or moral law, but through a concrete, relatable human life – the life of Jesus.

The Incarnation addresses the problem of evil and suffering. God doesn’t remain distant from our pain, but enters into it, sharing our burdens and offering hope amidst despair. This shared experience validates human suffering and points towards ultimate redemption.

Furthermore, the Incarnation provides a new lens through which to view humanity. We are not merely flawed creatures, but beings created in the image of God, capable of participating in divine life. Jesus, as the perfect image of God, restores and elevates human nature.

The Atonement: Why Did God Become Man?

Lewis tackles the challenging question of why God would willingly endure the suffering of human existence. He posits that the Incarnation wasn’t merely about revealing God’s character, but about rectifying a fundamental problem: humanity’s separation from God due to sin.

He explains that human actions have consequences, violating the moral law and creating a debt that must be paid. This debt isn’t simply a matter of rules, but a disruption of the very fabric of creation, demanding justice and restoration.

The Atonement, therefore, is God’s solution to this dilemma. Jesus, as fully God and fully human, takes upon himself the penalty for human sin, satisfying divine justice and bridging the gap between humanity and the divine.

Lewis emphasizes that this isn’t a case of God appeasing his own wrath, but of a loving Father rescuing his children from self-destruction. The sacrifice of Jesus demonstrates God’s immense love and offers a path to forgiveness and reconciliation.

Book III: Christian Behavior

This section explores the practical implications of Christian belief, focusing on virtues, sins, and the path toward spiritual growth and a transformed life.

Lewis guides readers through essential Christian practices, emphasizing forgiveness, humility, and charitable acts as cornerstones of a meaningful faith.

Chapter 1: The Three Virtues

Lewis identifies Faith, Hope, and Charity as the three theological virtues, foundational to Christian living and distinct from merely human qualities. He clarifies that these aren’t feelings, but powers of being, gifts received from God enabling us to participate in the divine nature.

Faith, in Lewis’s view, isn’t simply believing that God exists, but a trusting in God – a willingness to act as if His promises are true, even when evidence is lacking. Hope transcends mere wishful thinking; it’s a confident expectation of God’s ultimate victory and goodness, anchoring us amidst suffering.

Charity, or Love, is presented as the greatest of these virtues, encompassing both love for God and love for neighbor. It’s not a feeling, but a deliberate orientation of the will toward the good of others, mirroring God’s own selfless love. Lewis emphasizes that these virtues aren’t achieved through self-effort, but are cultivated through prayer and surrender to God’s grace, transforming our character from within.

Discussion points should center on how these virtues differ from secular understandings, and how actively cultivating them impacts daily life and relationships.

Chapter 2: The Seven Deadly Sins

Lewis explores the traditional Seven Deadly Sins – Pride, Greed, Lust, Envy, Gluttony, Wrath, and Sloth – not as isolated vices, but as distortions of natural human desires. He argues they aren’t simply wrong actions, but root attitudes that corrupt our motivations and relationships.

He emphasizes that sins aren’t equal; spiritual sins, those directed against God, are far more serious than sins of the flesh, as they sever our connection to the source of all goodness. Each sin is examined as a turning away from God and a misdirection of our innate longings.

Lewis clarifies that these sins aren’t merely forbidden, but understood as self-destructive forces that ultimately diminish our capacity for joy and fulfillment. He stresses the importance of recognizing these tendencies within ourselves and seeking God’s help to overcome them.

Discussion should focus on identifying these sins in contemporary culture and personal experience, and exploring how acknowledging them can lead to genuine repentance and spiritual growth.

Pride as the Greatest Sin

Lewis posits that Pride is the “utmost evil”, the most insidious and destructive of all sins. It isn’t merely vanity or arrogance, but a complete self-reliance, a belief that we need nothing beyond ourselves – including God. This self-sufficiency closes us off from grace and genuine humility.

He argues that Pride is the source of all other sins, as it’s the fundamental rejection of our dependence on God. It’s a desire to be “as God,” to control our own destiny and define our own morality, rather than submitting to divine authority.

Lewis illustrates how Pride manifests in various forms, from intellectual arrogance to a subtle sense of moral superiority. It’s a sin that easily hides, even within seemingly virtuous actions, if motivated by self-aggrandizement.

Discussion should center on recognizing the subtle ways Pride operates in our own lives, and exploring the liberating power of humility and dependence on God. Consider how acknowledging our limitations opens us to genuine connection and spiritual growth.

Sexuality, Pleasure, and Chastity in Christian Thought

Lewis addresses the Christian view of sexuality, emphasizing that it’s not inherently sinful, but a powerful natural desire that requires proper ordering within the context of marriage. He critiques the modern tendency to either idolize or demonize sex, advocating for a balanced perspective.

He clarifies that pleasure itself isn’t evil; God created our capacity for enjoyment. However, pleasure becomes problematic when it’s pursued as an end in itself, divorced from love and commitment. True joy, Lewis suggests, arises from rightly ordered desires.

Chastity, for Lewis, isn’t merely abstinence, but the appropriate control of all our desires – not just sexual ones. It’s about directing our affections towards God and others, rather than being enslaved by our impulses.

Discussion should explore how to navigate the complexities of sexuality and pleasure in a way that honors God and fosters healthy relationships. Consider the challenges of living out chastity in a culture that often prioritizes gratification.

Chapter 3: The Next Steps

Lewis outlines the practical implications of embracing Christian belief, moving beyond intellectual assent to a life of active discipleship. He emphasizes that becoming a Christian isn’t a one-time event, but a continuous process of growth and transformation.

Forgiveness and reconciliation are central to this journey. Lewis stresses the importance of confessing our sins, receiving God’s grace, and extending forgiveness to others, mirroring the divine forgiveness we’ve received.

He highlights the virtues of charity and humility as essential characteristics of the Christian life. True love, according to Lewis, isn’t merely a feeling, but a deliberate act of will, focused on the well-being of others.

Discussion should center on how to integrate faith into daily life, overcome obstacles to spiritual growth, and cultivate a heart of compassion. Explore practical steps for living out Christian values in a challenging world.

Forgiveness and Reconciliation

Lewis powerfully argues that the Christian faith fundamentally revolves around forgiveness – both divine and human. He explains that recognizing our own need for forgiveness is the first step towards extending it to others, mirroring God’s unconditional grace.

The concept of reconciliation is presented as a restoration of broken relationships, not merely a dismissal of offenses. True forgiveness requires acknowledging the hurt caused, seeking repentance where necessary, and actively working towards healing.

He challenges the notion of earning forgiveness, emphasizing that it is a free gift offered by God through Christ’s sacrifice. This understanding liberates us from the burden of guilt and empowers us to forgive others as we have been forgiven.

Discussion points should explore the difficulties of forgiveness, the importance of confession, and the transformative power of reconciliation in personal relationships and broader society. Consider practical applications of these principles.

The Importance of Charity and Humility

C.S. Lewis underscores that genuine Christian behavior is deeply rooted in the virtues of charity and humility. He posits that charity, or selfless love, isn’t merely a feeling but an active commitment to the well-being of others, even – and especially – those we find difficult.

Humility, for Lewis, is not self-deprecation but a realistic assessment of our own limitations and dependence on God. It’s recognizing that any good we possess is a gift, not an achievement, and directing praise where it’s due.

These virtues are intertwined; humility prevents us from pridefully judging others, while charity compels us to act with compassion and understanding. Lewis argues that neglecting either leads to spiritual imbalance and distorted relationships.

Study questions should focus on how to cultivate these virtues in daily life, overcoming self-centeredness, and practicing empathy. Explore the contrast between charitable acts and self-serving motivations, and the role of grace in fostering humility.

Further Exploration and Discussion

Extend your understanding by applying Mere Christianity’s principles to contemporary issues. Delve into additional resources and engage in thoughtful conversations about faith’s relevance today.

Applying Mere Christianity to Modern Life

C.S. Lewis’s enduring work isn’t merely a historical or philosophical exercise; it’s profoundly relevant to the challenges and complexities of the 21st century. How do the core arguments presented in Mere Christianity – concerning reason, morality, and the nature of God – address contemporary debates surrounding ethics, purpose, and meaning?

Consider the implications of Lewis’s insights on issues like social justice, political polarization, and the pervasive sense of spiritual longing in modern society. Can the concept of the “Tao” – the universal moral law – provide a framework for navigating ethical dilemmas in a rapidly changing world? How does Lewis’s understanding of human desire inform our pursuit of happiness and fulfillment in an age of consumerism and instant gratification?

Furthermore, explore how the Christian virtues of humility, charity, and forgiveness can be practiced in everyday life, fostering more compassionate and meaningful relationships. Engage with current events through the lens of Lewis’s theological framework, seeking to discern God’s call to action and contribute to a more just and loving world. This requires critical thinking and a willingness to apply timeless truths to modern contexts.

Resources for Continued Study

To deepen your exploration of C.S. Lewis’s Mere Christianity and its enduring themes, several resources are readily available. Explore the C.S. Lewis Foundation’s website (cslewisfoundation.org) for articles, lectures, and study materials. Numerous study guides supplement the book, offering discussion questions and insightful commentary – consider those specifically designed for group settings.

Delve into Lewis’s other works, such as The Screwtape Letters and The Problem of Pain, to gain a broader understanding of his theological perspective. Online resources, including podcasts and video lectures, provide accessible introductions to Lewis’s thought. Academic journals and scholarly articles offer in-depth analyses of Mere Christianity’s historical and philosophical context.

Don’t overlook the wealth of commentaries and critical essays available in libraries and bookstores. Engage with online communities dedicated to C.S. Lewis, fostering discussion and sharing insights with fellow enthusiasts. Remember that continued study and reflection are key to fully appreciating the richness and relevance of Lewis’s timeless message.